Fire retardant epoxies are epoxy resin systems formulated to minimize the flammability of materials, and thus reduce the longevity and spread of fire. They incorporate various additives or fillers that effectively hinder or delay combustion when subjected to heat or flames. These specialized components find widespread application in industries where fire safety is paramount, including aerospace, construction, electronics, and automotive.

Fire resistance is increasingly becoming an important requirement in specifying adhesive systems. Across a wide range of applications, a fire retardant adhesive system can offer a safer use of many devices and systems. Incidents associated with fire outbreaks, resulting in significant damage and personal injury, have focused attention on how materials perform in combating the effects of fire. A number of approaches mitigate the destruction when a fire breaks out, and a fire retardant epoxy resin system may play an important role in this effort.

In this Blog, we will examine the composition and functionality of a fire retardant epoxy. We will also look into its various applications across different industries.

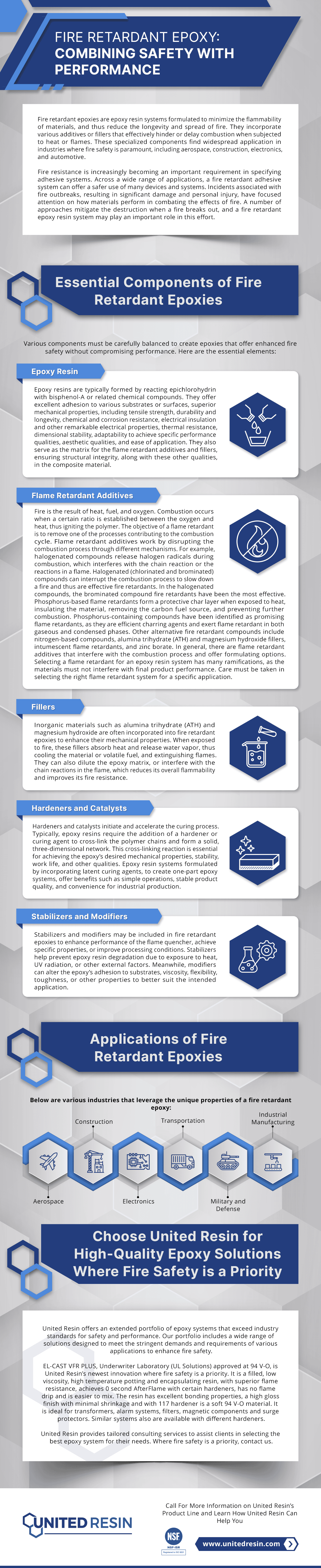

Essential Components of Fire Retardant Epoxies

Various components must be carefully balanced to create epoxies that offer enhanced fire safety without compromising performance. Here are the essential elements:

Epoxy Resin

Epoxy resins are typically formed by reacting epichlorohydrin with bisphenol-A or related chemical compounds. They offer excellent adhesion to various substrates or surfaces, superior mechanical properties, including tensile strength, durability and longevity, chemical and corrosion resistance, electrical insulation and other remarkable electrical properties, thermal resistance, dimensional stability, adaptability to achieve specific performance qualities, aesthetic qualities, and ease of application. They also serve as the matrix for the flame retardant additives and fillers, ensuring structural integrity, along with these other qualities, in the composite material.

Flame Retardant Additives

Fire is the result of heat, fuel, and oxygen. Combustion occurs when a certain ratio is established between the oxygen and heat, thus igniting the polymer. The objective of a flame retardant is to remove one of the processes contributing to the combustion cycle. Flame retardant additives work by disrupting the combustion process through different mechanisms. For example, halogenated compounds release halogen radicals during combustion, which interferes with the chain reaction or the reactions in a flame. Halogenated (chlorinated and brominated) compounds can interrupt the combustion process to slow down a fire and thus are effective fire retardants. In the halogenated compounds, the brominated compound fire retardants have been the most effective. Phosphorus-based flame retardants form a protective char layer when exposed to heat, insulating the material, removing the carbon fuel source, and preventing further combustion. Phosphorus-containing compounds have been identified as promising flame retardants, as they are efficient charring agents and exert flame retardant in both gaseous and condensed phases. Other alternative fire retardant compounds include nitrogen-based compounds, alumina trihydrate (ATH) and magnesium hydroxide fillers, intumescent flame retardants, and zinc borate. In general, there are flame retardant additives that interfere with the combustion process and offer formulating options. Selecting a flame retardant for an epoxy resin system has many ramifications, as the materials must not interfere with final product performance. Care must be taken in selecting the right flame retardant system for a specific application.

Fillers

Inorganic materials such as alumina trihydrate (ATH) and magnesium hydroxide are often incorporated into fire retardant epoxies to enhance their mechanical properties. When exposed to fire, these fillers absorb heat and release water vapor, thus cooling the material or volatile fuel, and extinguishing flames. They can also dilute the epoxy matrix, or interfere with the chain reactions in the flame, which reduces its overall flammability and improves its fire resistance.

Hardeners and Catalysts

Hardeners and catalysts initiate and accelerate the curing process. Typically, epoxy resins require the addition of a hardener or curing agent to cross-link the polymer chains and form a solid, three-dimensional network. This cross-linking reaction is essential for achieving the epoxy’s desired mechanical properties, stability, work life, and other qualities. Epoxy resin systems formulated by incorporating latent curing agents, to create one-part epoxy systems, offer benefits such as simple operations, stable product quality, and convenience for industrial production.

Stabilizers and Modifiers

Stabilizers and modifiers may be included in fire retardant epoxies to enhance performance of the flame quencher, achieve specific properties, or improve processing conditions. Stabilizers help prevent epoxy resin degradation due to exposure to heat, UV radiation, or other external factors. Meanwhile, modifiers can alter the epoxy’s adhesion to substrates, viscosity, flexibility, toughness, or other properties to better suit the intended application.

Applications of Fire Retardant Epoxies

Below are various industries that leverage the unique properties of a fire retardant epoxy:

Aerospace

Fire retardant epoxy systems play a crucial role in enhancing safety and durability in the aerospace industry. The aerospace industry uses fire retardant epoxies to create aircraft components, including interior panels and interior cabin components, seat structures, and cargo compartments. They are used also in composite structures, for electrical potting and encapsulation, for thermal insulation, as adhesives and sealants, and as protective coatings. These epoxies are beneficial in the construction of drones and drone components. They help meet stringent safety regulations in the aerospace industry by enhancing fire resistance while maintaining structural integrity. As a result, aircraft are safer and more efficient.

Construction

In the construction sector, fire retardant epoxies are critical components in building safety and integrity, by enhancing fire resistance and containment. They find application in building materials such as fire doors, wall panels, and structural reinforcements. They are integral to fire-stop systems designed to prevent the spread of smoke and fire between building compartments. They help improve the fire resistance of structures, reducing the spread of flames and minimizing the risk of fire-related damage or collapse. The use of fire retardant systems in construction is guided by building codes and standards, designed to improve fire safety and thereby protect lives and property.

Electronics

Sensitive electronic components require protection from fire hazards. Fire retardant epoxy systems are widely used to encapsulate and pot electronic components, to safeguard these parts and help ensure reliable performance in high-temperature or other rough environments. Fire retardant epoxy systems may significantly reduce the risk of potential short circuits or overheating within the electronic device. These important systems are used for printed circuit board (PCB) coatings, for electrical and cable insulation, as underfill materials for circuit boards, for LED encapsulation, and in the manufacture of connectors and housing. These systems are designed to meet regulatory standards and requirements, such as the Underwriter Laboratory (UL Solutions) 94 standards for flammability.

Transportation

Fire retardant epoxies play a vital role in various modes of transportation, including automotive, rail or trains, and marine and ships. They are used in vehicle interior parts such as dashboards and door panels, battery housings for electric vehicles (EVs), engine compartments, in electronic parts such as sensors, and structural components, to enhance fire safety and meet regulatory requirements for passenger safety.

In the rail industry, there are similar uses in interior panels, seating, flooring, electrical insulation and electronic potting and encapsulation. Flame retardant epoxy systems are used importantly in the marine industry for construction and repair of ships, in particular in engine rooms and electrical control rooms. As noted above, flame retardant epoxy systems are crucial for safety of aircraft components. Similar uses are applied in the manufacture of public transport vehicles and recreational and other specialty vehicles. All are designed to meet regulatory safety standards to enhance safety and save lives and mitigate property damage.

Military and Defense

Military applications often require materials with superior fire resistance and durability, to enhance the safety and performance of equipment, vehicles and structures. Given the crucial importance of combat operations and the challenging, hazardous, high-risk environments of military and defense operations, stringent safety requirements are a necessity. The importance of flame retardant epoxy systems as discussed in all the applications and industries noted above generally are fully applicable to the military and defense industry. Critical uses are found in vehicle protection, aerospace applications, electronic and electrical systems, weapons and munition systems manufacturing and storage, protective gear manufacturing, sealings and protective coatings, fire-stop systems and in composite materials made with flame retardant materials. These materials are used in a wide variety of applications, including drone airframes, to enhance safety and performance.

Fire retardant epoxies are used in military vehicles, aircraft, drones and naval vessels to enhance survivability and protect personnel and equipment from fire-related threats.

Industrial Manufacturing

Various industrial processes involve handling flammable materials or operating in environments where fire hazards are prevalent. Fire retardant epoxies are employed in equipment enclosures, machinery parts, and manufacturing facilities to reduce the risk of fire accidents. Their application includes many of the purposes discussed above to enhance fire safety and durability. These include uses as protective coatings, in electrical insulation and electrical potting and encapsulation, in structural and composite materials, as fire barrier or fire-stop systems, in cable and wire coatings, in storage containers, and in maintenance and repair. As with all the applications discussed above, these fire retardant materials create a safer environment to protect lives and property.

Choose United Resin for High-Quality Epoxy Solutions Where Fire Safety is a Priority

United Resin offers an extended portfolio of epoxy systems that exceed industry standards for safety and performance. Our portfolio includes a wide range of solutions designed to meet the stringent demands and requirements of various applications to enhance fire safety.

EL-CAST VFR PLUS, Underwriter Laboratory (UL Solutions) approved at 94 V-O, is United Resin’s newest innovation where fire safety is a priority. It is a filled, low viscosity, high temperature potting and encapsulating resin, with superior flame resistance, achieves 0 second AfterFlame with certain hardeners, has no flame drip and is easier to mix. The resin has excellent bonding properties, a high gloss finish with minimal shrinkage and with 117 hardener is a soft 94 V-O material. It is ideal for transformers, alarm systems, filters, magnetic components and surge protectors. Similar systems also are available with different hardeners.

United Resin provides tailored consulting services to assist clients in selecting the best epoxy system for their needs. Where fire safety is a priority, contact us.

The information presented in this Blog is intended for general background and informational purposes only and is not intended as advice pertaining to any product, application or process. We encourage you to contact us for information concerning your specific needs and requirements and to discover how United Resin may assist you.

Contact us today or request a quote to get started!