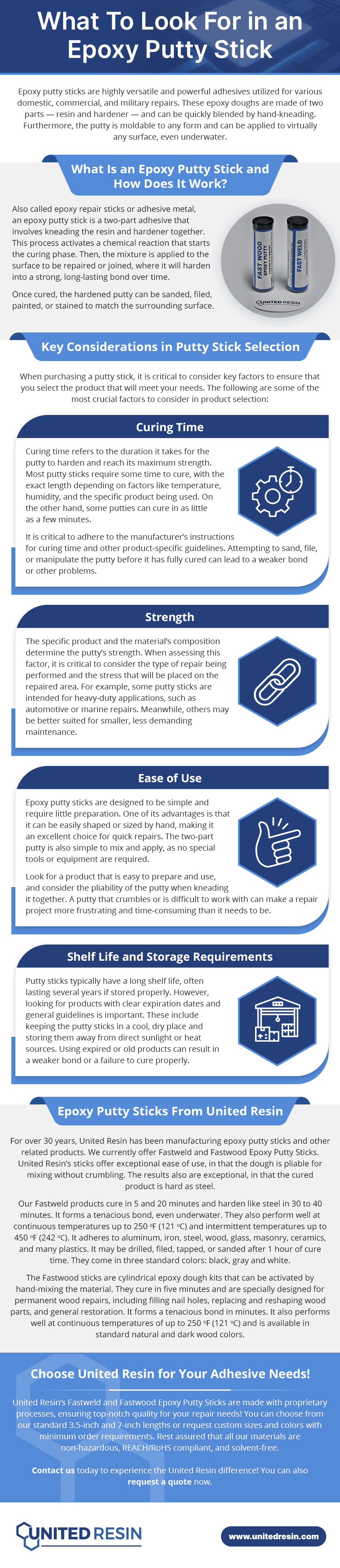

Epoxy putty sticks are highly versatile and powerful adhesives utilized for various domestic, commercial, and military repairs. These epoxy doughs are made of two parts — resin and hardener — and can be quickly blended by hand-kneading. Furthermore, the putty is moldable to any form and can be applied to virtually any surface, even underwater.

This article will explain how a putty stick works and what factors to consider when choosing the right product for your application.

What Is an Epoxy Putty Stick and How Does It Work?

Also called epoxy repair sticks or adhesive metal, an epoxy putty stick is a two-part adhesive that involves kneading the resin and hardener together. This process activates a chemical reaction that starts the curing phase. Then, the mixture is applied to the surface to be repaired or joined, where it will harden into a strong, long-lasting bond over time.

Once cured, the hardened putty can be sanded, filed, painted, or stained to match the surrounding surface.

Key Considerations in Putty Stick Selection

When purchasing a putty stick, it is critical to consider key factors to ensure that you select the product that will meet your needs. The following are some of the most crucial factors to consider in product selection:

Curing Time

Curing time refers to the duration it takes for the putty to harden and reach its maximum strength. Most putty sticks require some time to cure, with the exact length depending on factors like temperature, humidity, and the specific product being used. On the other hand, some putties can cure in as little as a few minutes.

It is critical to adhere to the manufacturer’s instructions for curing time and other product-specific guidelines. Attempting to sand, file, or manipulate the putty before it has fully cured can lead to a weaker bond or other problems.

Strength

The specific product and the material’s composition determine the putty’s strength. When assessing this factor, it is critical to consider the type of repair being performed and the stress that will be placed on the repaired area. For example, some putty sticks are intended for heavy-duty applications, such as automotive or marine repairs. Meanwhile, others may be better suited for smaller, less demanding maintenance.

Ease of Use

Epoxy putty sticks are designed to be simple and require little preparation. One of its advantages is that it can be easily shaped or sized by hand, making it an excellent choice for quick repairs. The two-part putty is also simple to mix and apply, as no special tools or equipment are required.

Look for a product that is easy to prepare and use, and consider the pliability of the putty when kneading it together. A putty that crumbles or is difficult to work with can make a repair project more frustrating and time-consuming than it needs to be.

Shelf Life and Storage Requirements

Putty sticks typically have a long shelf life, often lasting several years if stored properly. However, looking for products with clear expiration dates and general guidelines is important. These include keeping the putty sticks in a cool, dry place and storing them away from direct sunlight or heat sources. Using expired or old products can result in a weaker bond or a failure to cure properly.

Epoxy Putty Sticks From United Resin

For over 30 years, United Resin has been manufacturing epoxy putty sticks and other related products. We currently offer Fastweld and Fastwood Epoxy Putty Sticks. United Resin’s sticks offer exceptional ease of use, in that the dough is pliable for mixing without crumbling. The results also are exceptional, in that the cured product is hard as steel.

Our Fastweld products cure in 5 and 20 minutes and harden like steel in 30 to 40 minutes. It forms a tenacious bond, even underwater. They also perform well at continuous temperatures up to 250 ℉ (121 ℃) and intermittent temperatures up to 450 ℉ (242 ℃). It adheres to aluminum, iron, steel, wood, glass, masonry, ceramics, and many plastics. It may be drilled, filed, tapped, or sanded after 1 hour of cure time. They come in three standard colors: black, gray and white.

The Fastwood sticks are cylindrical epoxy dough kits that can be activated by hand-mixing the material. They cure in five minutes and are specially designed for permanent wood repairs, including filling nail holes, replacing and reshaping wood parts, and general restoration. It forms a tenacious bond in minutes. It also performs well at continuous temperatures of up to 250 ℉ (121 ℃) and is available in standard natural and dark wood colors.

Choose United Resin for Your Adhesive Needs!

United Resin’s Fastweld and Fastwood Epoxy Putty Sticks are made with proprietary processes, ensuring top-notch quality for your repair needs! You can choose from our standard 3.5-inch and 7-inch lengths or request custom sizes and colors with minimum order requirements. Rest assured that all our materials are non-hazardous, REACH/RoHS compliant, and solvent-free.

Contact us today to experience the United Resin difference! You can also request a quote now.